Light Material Drying System Production

Light Material Drying System Production

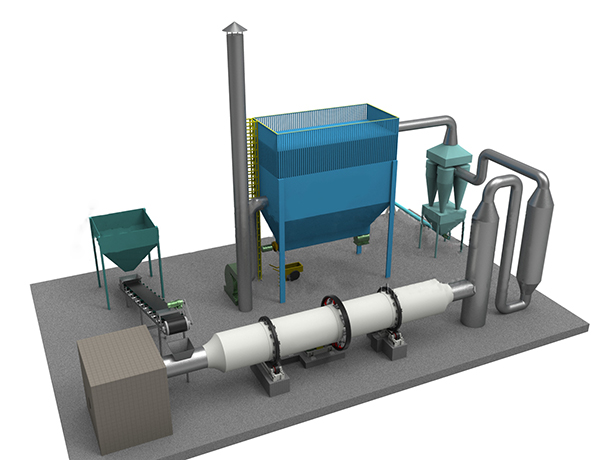

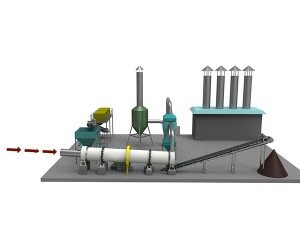

Selelekela sa Tsamaiso

Lilemong tsa morao tjena, ka ho eketseha ha mehloli ea tikoloho, tšebeliso e pharaletseng ea matla a biomass e se e le ea bohlokoa le ho feta ho rona.Ka lebaka la mongobo o phahameng oa sawdust, lehong le robehileng, le lebisang mollong o sa fellang, ho fella ka hore tlhase e chese mokotla oa lerōle ka morao ho semela se omisang, se sa bakiseng feela mesi e feteletseng, empa hape e na le litšenyehelo tse phahameng. ho fetola mokotla wa lerole.Ts'ebetsong ea ho hlahisa lihlahisoa tsa lehong le mafura a biomass a nang le boleng bo phahameng ba ho tuka, li-chips tsa patsi le li-dregs tse robehileng lia hlokahala ho etsa mokhoa oa ho omisa.

Phallo ea Ts'ebetso

Ka mor'a ho kenngoa ka har'a hopper, tlas'a ts'ebetso ea matla a khoheli, thepa e tala e tla oela holim'a lebanta la conveyor le behiloeng ka tlas'a hopper, ebe le tla fetisetsoa mochine oa ho hlahloba, boholo, hlobo le lintho tse ling tse sa tloaelehang. e arotsoe ka mor'a ho hlahlojoa, 'me likaroloana tsa junifomo li tla fetisetsoa pheletsong ea ho fepa ea se omisang (Moqomo o le mong kapa mochini o omisang li-cylinder tse tharo o tla khethoa ho ea ka boemo ba ts'ebeletso) ke morekisi oa lebanta ka tlas'a mochini o hlahlobang.Qetello ea phepelo ea se omisitsoeng e hokahane le mohloli oa mocheso 'me pheletso ea ho tsoa e hokahane le liphaephe tsa moea oa pulse.Lerako la mollo le tla hlongoa ka setofong se chesang se chesang e le ho netefatsa polokeho ea ts'ebetso ea ho omisa, ho felisa ts'ebetso ea lintho tse tukang ka har'a se omisang, 'me mocheso o fetang ka pipe o tla kenngoa pakeng tsa setofo se chesang le mocheso. se omisang joalo ka karolo e thibelang mocheso.Thepa e tla tlisoa ka har'a phala ea pulse e fetotsoeng ka bophara ka mor'a ho omisoa le ho felloa ke metsi ka lekhetlo la pele ka har'a se omisang, e tla be e le ka mokhoa o belang o emisitsoeng ka bophara bo boholo ba phala ea pulse, ebe e omisoa kapele. ka mor'a ho kopana le moea o khathetseng oa mocheso o tsoang ho se omisang.'Me thepa e tla lelekoa ka phala ea pulse ke meea e matla' me e isoa sethaleng sa pele sa leholiotsoana ha metsi a eona a fihla ho tlhokahalo ea moralo, 'me 80% ea thepa e omisitsoeng e tla bokelloa, ebe e kena sethaleng sa bobeli sa leholiotsoana. ka mor'a hore u fete ka har'a fene e hlohlellelitsoeng ho bokella thepa e ka letsohong le letšehali.Mokhahlelo oa bobeli oa leholiotsoana o ka nkeloa sebaka ke mokelli oa lerōle oa mofuta oa mokotla.

Melemo ea Tsamaiso

Matla a matla a ho omisa ka nako e khuts'oane ea ho omisa

Sesebelisoa sa ho omisa lisebelisoa tse bobebe se na le moralo o tsoetseng pele, o lumellang thepa hore e be le puisano e felletseng ho omisitsoeng, sebaka se felletseng sa likaroloana ke sebaka se sebetsang sa ho omisa, mme se na le matla a matla a ho omisa.Ka mochini o omisang moea oa pulse, nako ea ho omisa ke halofo feela ea se omisang se tloaelehileng, ts'ebetso ea mochini o omisang e eketseha haholo.

Theko e tlase ea ho omisa ka katleho e phahameng ea ho omisa

Sistimi ea ho omisa thepa e bobebe e na le sebopeho se tsoetseng pele, se nang le sebaka se senyenyane se koahetsoeng ka mabenkele, se bonolo ho hahoa le ho se lokisa.Matla a mocheso a ka fihla ho 90% ha o omisa metsi a sa tlangoa.

Phello e ntle ea ho omisa e nang le boemo bo phahameng ba automation

Mongobo oa ho qetela o tsitsitse (10% -13%) ka mor'a hore lisebelisoa tse tloaelehileng tsa leseli li omisoe, 'me lintho tse omisitsoeng ha li na litšila.Setofo se chesang se chesang se ka tsamaisana le alamo ea mocheso o phahameng haholo, sesebelisoa sa ho shebella lelakabe, alamo ea mocheso, sesebelisoa sa ho itšehla thajana, se ka netefatsang polokeho ea mollo.

Tekheniki Parameters

| Mohlala | Bophara ba silinda(mm) | Bolelele ba silinda(mm) | Bophahamo ba cylinder(m3) | Lebelo la cylinder rotary (r/min) | Matla(kW) | Boima (t) |

| VS0.6x5.8 | 600 | 5800 | 1.7 | 1-8 | 3 | 2.9 |

| VS0.8x8 | 800 | 8000 | 4 | 1-8 | 4 | 3.5 |

| VS1x10 | 1000 | 10000 | 7.9 | 1-8 | 5.5 | 6.8 |

| VS1.2x5.8 | 1200 | 5800 | 6.8 | 1-6 | 5.5 | 6.7 |

| VS1.2x8 | 1200 | 8000 | 9 | 1-6 | 5.5 | 8.5 |

| VS1.2x10 | 1200 | 10000 | 11 | 1-6 | 7.5 | 10.7 |

| VS1.2x11.8 | 1200 | 11800 | 13 | 1-6 | 7.5 | 12.3 |

| VS1.5x8 | 1500 | 8000 | 14 | 1-5 | 11 | 14.8 |

| VS1.5x10 | 1500 | 10000 | 17.7 | 1-5 | 11 | 16 |

| VS1.5x11.8 | 1500 | 11800 | 21 | 1-5 | 15 | 17.5 |

| VS1.5x15 | 1500 | 15000 | 26.5 | 1-5 | 15 | 19.2 |

| VS1.8x10 | 1800 | 10000 | 25.5 | 1-5 | 15 | 18.1 |

| VS1.8x11.8 | 1800 | 11800 | 30 | 1-5 | 18.5 | 20.7 |

| VS1.8x15 | 1800 | 15000 | 38 | 1-5 | 18.5 | 26.3 |

| VS1.8x18 | 1800 | 18000 | 45.8 | 1-5 | 22 | 31.2 |

| VS2x11.8 | 2000 | 11800 | 37 | 1-4 | 18.5 | 28.2 |

| VS2x15 | 2000 | 15000 | 47 | 1-4 | 22 | 33.2 |

| VS2x18 | 2000 | 18000 | 56.5 | 1-4 | 22 | 39.7 |

| VS2x20 | 2000 | 20000 | 62.8 | 1-4 | 22 | 44.9 |

| VS2.2x11.8 | 2200 | 11800 | 44.8 | 1-4 | 22 | 30.5 |

| VS2.2x15 | 2200 | 15000 | 53 | 1-4 | 30 | 36.2 |

| VS2.2x18 | 2200 | 18000 | 68 | 1-4 | 30 | 43.3 |

| VS2.2x20 | 2200 | 20000 | 76 | 1-4 | 30 | 48.8 |

| VS2.4x15 | 2400 | 15000 | 68 | 1-4 | 30 | 43.7 |

| VS2.4x18 | 2400 | 18000 | 81 | 1-4 | 37 | 53 |

| VS2.4x20 | 2400 | 20000 | 91 | 1-4 | 37 | 60.5 |

| VS2.4x23.6 | 2400 | 23600 | 109 | 1-4 | 45 | 69.8 |

| VS2.8x18 | 2800 | 18000 | 111 | 1-3 | 45 | 62 |

| VS2.8x20 | 2800 | 20000 | 123 | 1-3 | 55 | 65 |

| VS2.8x23.6 | 2800 | 23600 | 148 | 1-3 | 55 | 70 |

| VS2.8x28 | 2800 | 28000 | 172 | 1-3 | 75 | 75 |

| VS3x20 | 3000 | 20000 | 141 | 1-3 | 55 | 75 |

| VS3x23.6 | 3000 | 23600 | 170 | 1-3 | 75 | 85 |

| VS3x28 | 3000 | 28000 | 198 | 1-3 | 90 | 91 |

| VS3.2x23.6 | 3200 | 23600 | 193 | 1-3 | 90 | 112 |

| VS3.2x32 | 3200 | 32000 | 257 | 1-3 | 110 | 129 |

| VS3.6x36 | 3600 | 36000 | 366 | 1-3 | 132 | 164 |

| VS3.8x36 | 3800 | 36000 | 408 | 1-3 | 160 | 187 |

| VS4x36 | 4000 | 36000 | 452 | 1-3 | 160 | 195 |

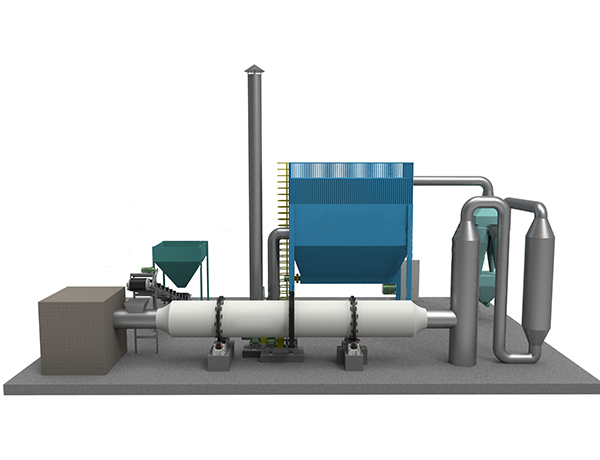

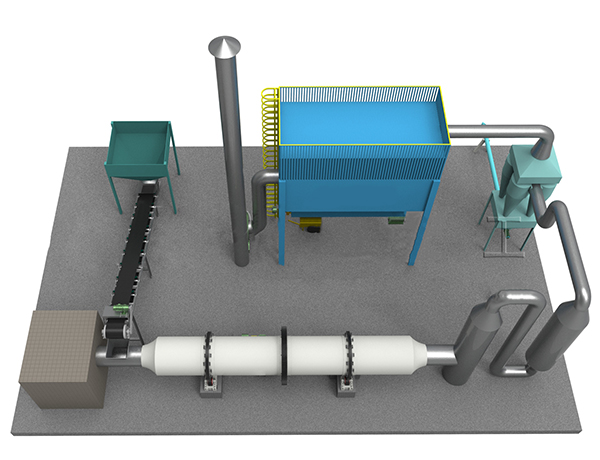

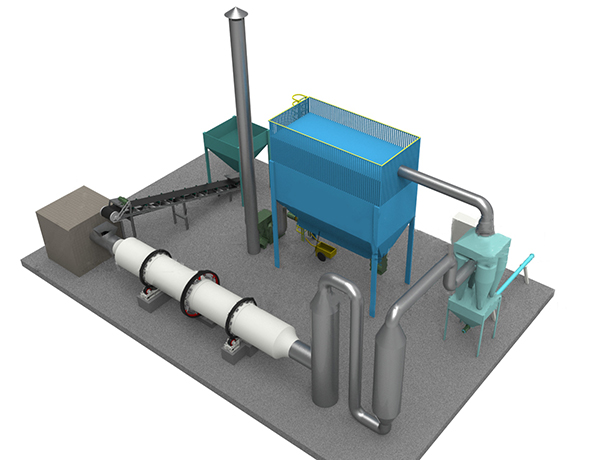

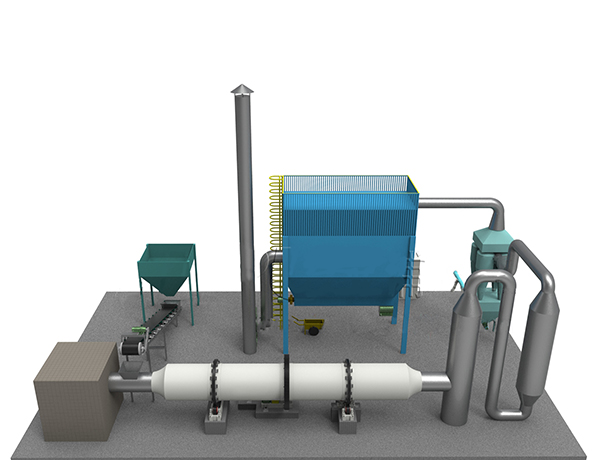

Litšoantšo tsa libaka tse sebetsang