Granular Material Omisa Sistimi

Granular Material Omisa Sistimi

Melemo ea Tsamaiso

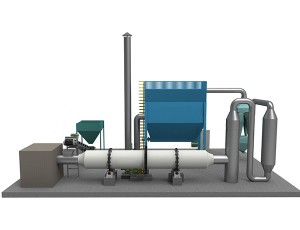

Matla a phahameng a mocheso

Lintho tse bolokang mocheso tse nang le ho hanyetsa mocheso o phahameng, ho kopantsoe le tšobotsi ea tšebeliso ea mocheso ea li-cylinder tse tharo, phello ea ho boloka matla e hlakile.

Letsete la thepa e tlaase

Thepa ea mocheso ke <50 ℃, e ka kenngoa ka ho toba ka tlung ea polokelo ea thepa, 'me sesebelisoa sa ho pholile ha se hlokehe;mocheso oa khase ea mohatla o tlase, thepa ea ho tlosa lerōle e na le bophelo bo bolelele ba tšebeletso.

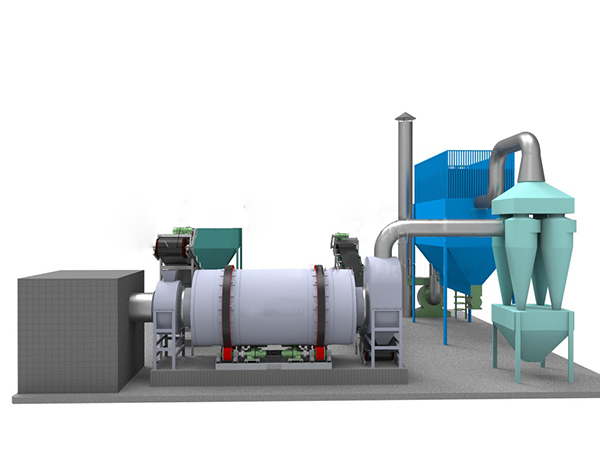

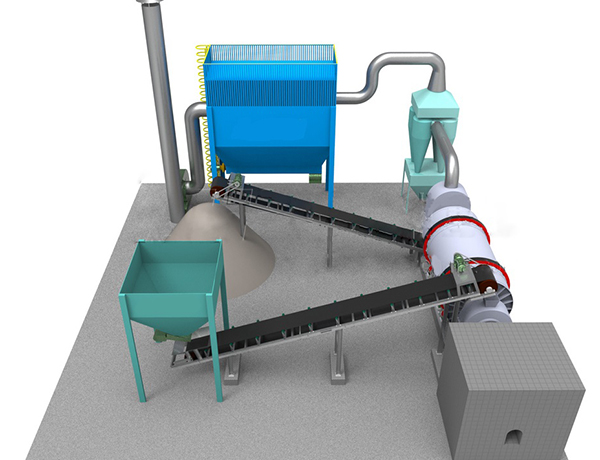

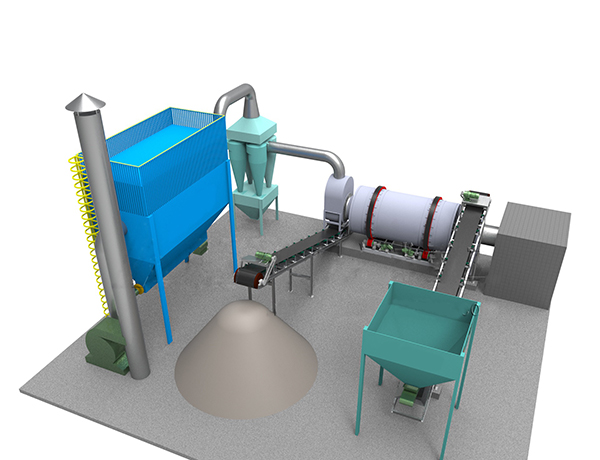

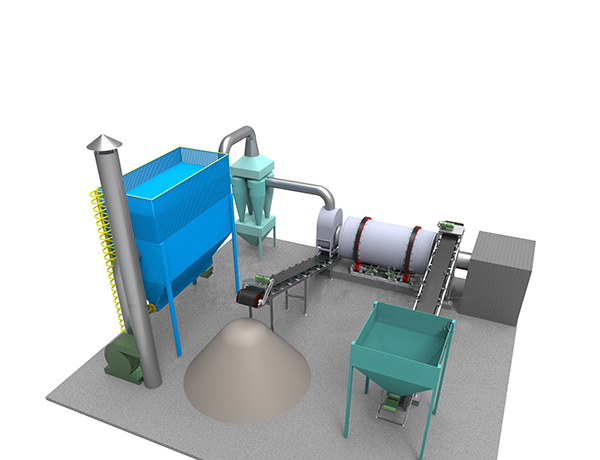

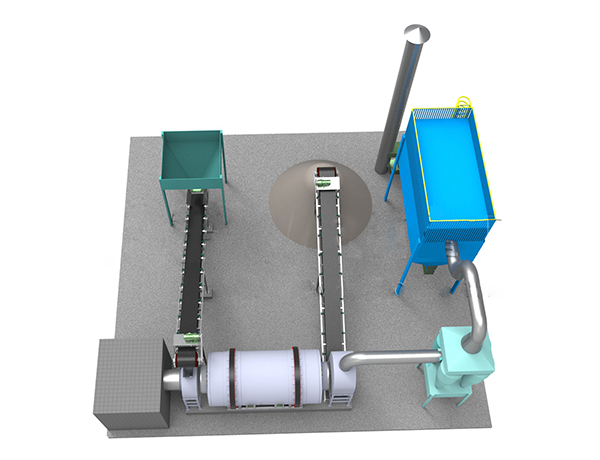

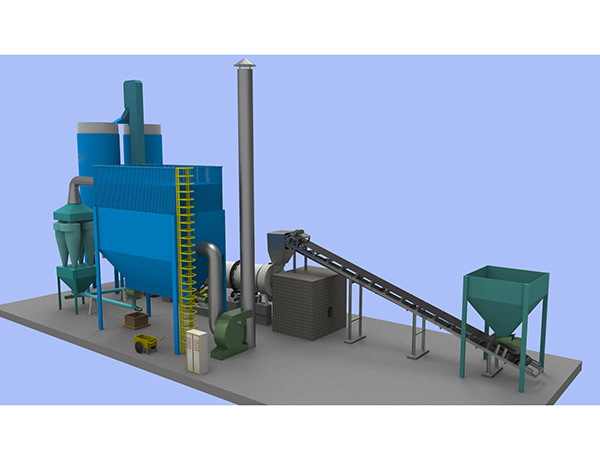

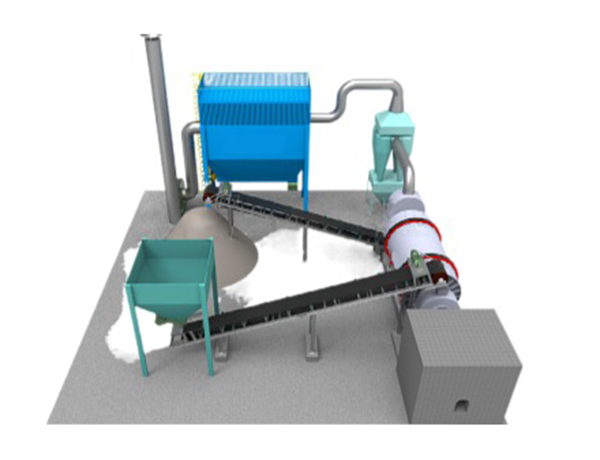

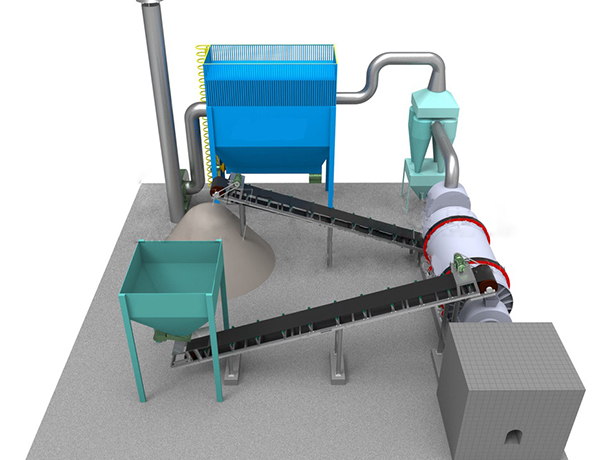

Sebaka se senyenyane sa fatše, se bonolo ho se kenya

Sebaka sa eona se koahetsoeng ke 50% ho feta sa se omisang silindara e le 'ngoe, matsete a kaho a fokotsoe ka 50% mme tšebeliso ea motlakase e fokotsehile ka 60%, sebopeho sa sistimi ea ho omisa se kopane le phallo e bonolo ea ts'ebetso.

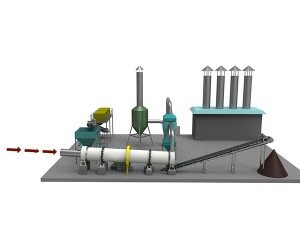

Molao-motheo oa ho Sebetsa

Thepa e tšeloa ka sebōping leha e le qetellong ea sebōpi (lehlakoreng le phahameng la silinda).Hobane cylinder e sekametse 'me e potoloha butle, thepa e tsamaea le selikalikoe hammoho le tataiso ea axial (ho tloha lehlakoreng le holimo ho ea tlaase).Kamora ho fetela phetohong ea 'mele le ea lik'hemik'hale, lisebelisoa li kena mochining o pholileng ka sekoaelo sa sebōpi kamora ho qeta ho bala.Mafura a tšeloa ka hloohong ea sebōpi ka hlooho ea sebōpi, 'me khase ea ho ntša metsi e tla tsoa qetellong ea sebōpi ka mor'a ho fapanyetsana mocheso le lintho tse bonahalang.

Litekanyetso tsa Tekheniki tsa Dryer e meraro ea Cylinder

| Mohlala | Lintlha tsa cylinder | Bokhoni (t/h) | Lebelo la cylinder rotary (r/mots) | Matla (kW) | ||||

| Bophara ba cylinder e ka ntle (m) | Bolelele ba ka ntle ba silindara (m) | Bophahamo ba cylinder (m3) | Noka lehlabathe | Fofa molora | Slag | |||

| VS6203 | 1.6 | 1.8 | 3.6 | 2-3 | 1-2 | 1-2 | 3-10 | 4 |

| VS6205 | 2 | 2 | 6.28 | 4-5 | 2-3 | 3-4 | 3-10 | 5.5 |

| VS6210 | 2.2 | 2.5 | 9.5 | 8-10 | 4-5 | 6-8 | 3-10 | 7.5 |

| VS6215 | 2.5 | 2.8 | 13.7 | 12-15 | 7-8 | 10-12 | 3-10 | 11 |

| VS2×4 | 2 | 4 | 12.56 | 8-12 | 4-6 | 8-10 | 3-10 | 3x2 |

| VS2×5 | 2 | 5 | 15.7 | 12-15 | 6-7 | 10-13 | 3-10 | 4x2 |

| VS2×6 | 2 | 6 | 18.84 | 20-25 | 10-17 | 20-27 | 3-10 | 7.5×2 |

| VS2.2×4.5 | 2.2 | 4.5 | 17.09 | 14-18 | 7-9 | 12-15 | 3-10 | 5.5×2 |

| VS2.5×6 | 2.5 | 6.5 | 31.89 | 23-28 | 10-13 | 20-22 | 3-10 | 5.5×4 |

| VS2.7×7 | 2.7 | 7 | 40.5 | 30-35 | 20-25 | 27-45 | 3-10 | 7.5×4 |

| VS2.8×6 | 2.8 | 6 | 36.9 | 30-35 | 15-18 | 25-30 | 3-10 | 5.5×4 |

| VS3×6 | 3 | 6 | 42.39 | 35-40 | 18-20 | 32-35 | 3-10 | 7.5×4 |

| VS3×7 | 3 | 7 | 49.46 | 40-45 | 20-25 | 35-40 | 3-10 | 7.5×4 |

| VS3.2×7 | 3.2 | 7 | 56.26 | 45-50 | 25-30 | 40-45 | 3-10 | 11x4 |

| VS3.2×8 | 3.2 | 8 | 64.3 | 50-55 | 30-35 | 45-50 | 3-10 | 11x4 |

| VS3.6×8 | 3.6 | 8 | 81.38 | 60-70 | 35-40 | 60-65 | 3-10 | 15x4 |

| VS3.8×9 | 3.8 | 9 | 102 | 70-80 | 40-45 | 70-75 | 3-10 | 15x4 |

| VS4×10 | 4 | 10 | 125.6 | 90-100 | 45-50 | 80-90 | 3-10 | 18.5×4 |

| VS4.2×8.5 | 4.2 | 8.5 | 117.7 | 80-100 | 45-60 | 80-90 | 3-10 | 18.5×4 |

Lihlahisoa tse omisitsoeng