Sistimi ea ho omisa ea lisebelisoa tse phahameng tsa mongobo

Sistimi ea ho omisa ea lisebelisoa tse phahameng tsa mongobo

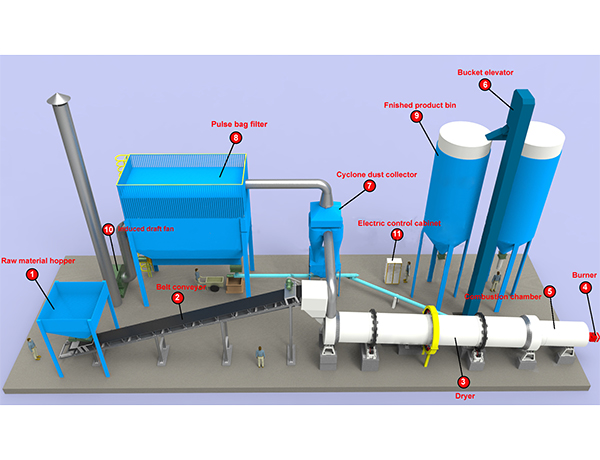

Tlhaloso ea Lintho

Mokhoa oa khale oa ho lahla moiteli oa mehlape ke ho rekisoa e le moiteli oa masimo ka theko e tlase, 'me o sebelisoe ka kotloloho e le manyolo a temo, boleng ba ona moruong ha se ho hlahlojoa le ho sebelisoa ka botlalo.Ha e le hantle, tsena ke mehloli ea bohlokoa ea furu le manyolo, haeba e ka ntlafatsoa le ho sebelisoa, e tla ba le bohlokoa bo boholo ho tlhahiso ea manyolo a manyolo, ho nts'etsopele ea indasteri ea ho lema le ea ho ikatisa, ho khothalletsa tlhahiso ea temo le chelete, ho boloka matla le Lijo tse tala tse se nang tšilafalo, nts'etsopele ea temo e tala, ho sireletsa tikoloho le bophelo bo botle ba batho.

Phallo ea Ts'ebetso

Thepa e hlakotsoeng e tla isoa hloohong e fepang ea se omisang ka "screw conveyor" ka mor'a hore e hasane, ebe e tla romelloa ka hare ho se omisang ka sesebelisoa se se nang matla sa spiral sealing (theknoloji ea patent ea k'hamphani ea rona), ebe e feta har'a tse 'maloa. libaka tse latelang tsa ho sebetsa ka mor'a ho kena ka har'a dryer:

1. Sebaka sa lintho tse etellang pele

Thepa e tla kopana le mocheso o phahameng oa khatello e mpe ea moea ka mor'a hore e kene sebakeng sena 'me metsi a mangata a tla fetoha mouoane ka potlako,' me thepa e ke ke ea etsoa hore e be lintho tse khomarelang tlas'a ho sisinyeha ha poleiti e kholo ea tataiso ea angle lifting.

2. Sebaka sa ho hloekisa

Lesela la lintho tse bonahalang le tla thehoa ha seretse se phahamisoa sebakeng sena, 'me se tla etsa hore thepa e khomarele leboteng la cylinder ha e ntse e oela fatše,' me sesebelisoa sa ho hloekisa se kentsoe sebakeng sena (Lifting style stirring plate, X type second. nako e susumetsang poleiti, ketane e nang le tšusumetso, poleiti e nang le tšusumetso), thepa e ka tlosoa ka potlako leboteng la silinda ka sesebelisoa sa ho hloekisa, 'me sesebelisoa sa ho hloekisa se ka boela sa senya lisebelisoa tse kopantsoeng hammoho, e le ho eketsa sebaka sa phapanyetsano ea mocheso, ho eketsa. nako ea ho fapanyetsana mocheso, qoba ho hlahisa ketsahalo ea kotopo ea moea, ho ntlafatsa lebelo la ho omisa;

3. Sebaka sa poleiti ea ho phahamisa e sekametseng

Sebaka sena ke sebaka sa ho omisa mocheso o tlaase, slime ea sebaka sena e le mongobo o tlaase le boemo bo hlephileng, 'me ha ho na ntho ea ho khomarela sebakeng sena, lihlahisoa tse felileng li finyella litlhoko tsa mongobo ka mor'a phapanyetsano ea mocheso, ebe li kena qetellong. sebaka sa ho tsoa;

4. Sebaka sa ho qhala

Ha ho na lipoleiti tse sisinyehang sebakeng sena sa silinda ea se omisang, 'me thepa e tla be e theohetse boema-kepe ba ho ntša metsi.Thepa butle-butle e fetoha e hlephileng ka mor'a ho omisoa, 'me e lokolloa ho tloha qetellong ea ho ntša, ebe e romeloa sebakeng se khethiloeng ke sesebelisoa se tsamaisang,' me lerōle le letle le huloang hammoho le khase ea mohatla le bokelloa ke mokelli oa lerōle.

Moea o chesang o kena ka har'a mochini o omisang ho tloha pheletsong ea phepelo, 'me mocheso o fokotseha butle butle ka nako e ts'oanang ea phetisetso ea mocheso oa thepa,' me mouoane oa metsi o ntšoa ka tlas'a ho huloa ha fan e kentsoeng, ebe o kenngoa moeeng ka mor'a ho sebetsa. .

Melemo ea Tsamaiso

Matla a phahameng a mocheso, litšenyehelo tse tlaase tsa ho omisa

Sebopeho se secha sa ka hare, le ho matlafatsa ho hloekisoa ha thepa e qhalakaneng le mocheso oa mocheso, ho felisa ketsahalo e khomarelang ea lerako le ka hare la 'mele oa moqomo, e khona ho ikamahanya le mongobo oa lintho tse bonahalang le ho khomarela, sebaka sa ho fapanyetsana mocheso le katleho ea ho omisa lia eketseha.Mekhahlelo ea ts'ebetso e ka fetoloa ho latela lisebelisoa tse fapaneng, 'me phapanyetsano ea mocheso oa thepa e omisitsoeng e tletse ka botlalo.

Ho matha ka botšepehi, botsitso bo botle

Mofuta o mocha oa sesebelisoa sa ho fepa le ho ntša, o felisitse ts'ebetso ea polaka ho fepa, ho se ts'oanelehe, ho se sebetse hantle le ho khutla ha lintho tse bonahalang."Sesebelisoa sa "aligning roller" se amoheloa ke se omisang, se etsang hore selikalikoe se hulang le se bilikang se lule se kopana le linear, 'me se fokotsa haholo ho senyeha le ho sebelisoa ha matla. ho phatloha ha lebili la gear le lebili le tšehetsang, ts'ebetso ea silinda e tsitsitse ebile e ka tšeptjoa.

Mefuta e mengata e fapaneng ea mohloli oa mocheso o sebelisoang, ts'ireletso ea tikoloho le ho se silafatse

Mashala, oli, khase ea tlhaho, khase ea oli ea mokelikeli e ka sebelisoa e le mafura.E khethiloe ho latela litlhoko tsa thepa le melemo ea tlhaho ea lehae, ho ntlafatsa katleho ea tlhahiso le melemo ea moruo.

Boemo bo phahameng ba ho iketsetsa, ts'ireletso ea nako ea sebele

Sistimi ea taolo ea othomathike ea PLC e ka amoheloa ka har'a sistimi eohle, sistimi e na le lisebelisoa tse tsoetseng pele tsa tlhahlobo: tekanyo ea mocheso, taolo ea mocheso (e ka fetoloa ka nako efe kapa efe ho latela litlhoko tsa thepa), ts'ebetso ea alamo ea phoso ea othomathiki. tšireletso ea shutdown, joalo-joalo.

Tekheniki Parameters

| Mohlala | Bophara ba silinda(mm) | Bolelele ba silinda(mm) | Bophahamo ba cylinder(m3) | Lebelo la cylinder rotary (r/min) | Matla(kW) | Boima (t) |

| VS 0.6x5.8 | 600 | 5800 | 1.7 | 1-8 | 3 | 2.9 |

| VS 0.8x8 | 800 | 8000 | 4 | 1-8 | 4 | 3.5 |

| VS 1x10 | 1000 | 10000 | 7.9 | 1-8 | 5.5 | 6.8 |

| VS 1.2x5.8 | 1200 | 5800 | 6.8 | 1-6 | 5.5 | 6.7 |

| VS 1.2x8 | 1200 | 8000 | 9 | 1-6 | 5.5 | 8.5 |

| VS 1.2x10 | 1200 | 10000 | 11 | 1-6 | 7.5 | 10.7 |

| VS 1.2x11.8 | 1200 | 11800 | 13 | 1-6 | 7.5 | 12.3 |

| VS 1.5x8 | 1500 | 8000 | 14 | 1-5 | 11 | 14.8 |

| VS 1.5x10 | 1500 | 10000 | 17.7 | 1-5 | 11 | 16 |

| VS 1.5x11.8 | 1500 | 11800 | 21 | 1-5 | 15 | 17.5 |

| VS 1.5x15 | 1500 | 15000 | 26.5 | 1-5 | 15 | 19.2 |

| VS 1.8x10 | 1800 | 10000 | 25.5 | 1-5 | 15 | 18.1 |

| VS 1.8x11.8 | 1800 | 11800 | 30 | 1-5 | 18.5 | 20.7 |

| VS 1.8x15 | 1800 | 15000 | 38 | 1-5 | 18.5 | 26.3 |

| VS 1.8x18 | 1800 | 18000 | 45.8 | 1-5 | 22 | 31.2 |

| VS 2x11.8 | 2000 | 11800 | 37 | 1-4 | 18.5 | 28.2 |

| VS 2x15 | 2000 | 15000 | 47 | 1-4 | 22 | 33.2 |

| VS 2x18 | 2000 | 18000 | 56.5 | 1-4 | 22 | 39.7 |

| VS 2x20 | 2000 | 20000 | 62.8 | 1-4 | 22 | 44.9 |

| VS 2.2x11.8 | 2200 | 11800 | 44.8 | 1-4 | 22 | 30.5 |

| VS 2.2x15 | 2200 | 15000 | 53 | 1-4 | 30 | 36.2 |

| VS 2.2x18 | 2200 | 18000 | 68 | 1-4 | 30 | 43.3 |

| VS 2.2x20 | 2200 | 20000 | 76 | 1-4 | 30 | 48.8 |

| VS 2.4x15 | 2400 | 15000 | 68 | 1-4 | 30 | 43.7 |

| VS 2.4x18 | 2400 | 18000 | 81 | 1-4 | 37 | 53 |

| VS 2.4x20 | 2400 | 20000 | 91 | 1-4 | 37 | 60.5 |

| VS 2.4x23.6 | 2400 | 23600 | 109 | 1-4 | 45 | 69.8 |

| VS 2.8x18 | 2800 | 18000 | 111 | 1-3 | 45 | 62 |

| VS 2.8x20 | 2800 | 20000 | 123 | 1-3 | 55 | 65 |

| VS 2.8x23.6 | 2800 | 23600 | 148 | 1-3 | 55 | 70 |

| VS 2.8x28 | 2800 | 28000 | 172 | 1-3 | 75 | 75 |

| VS 3x20 | 3000 | 20000 | 141 | 1-3 | 55 | 75 |

| VS 3x23.6 | 3000 | 23600 | 170 | 1-3 | 75 | 85 |

| VS 3x28 | 3000 | 28000 | 198 | 1-3 | 90 | 91 |

| VS 3.2x23.6 | 3200 | 23600 | 193 | 1-3 | 90 | 112 |

| VS 3.2x32 | 3200 | 32000 | 257 | 1-3 | 110 | 129 |

| VS 3.6x36 | 3600 | 36000 | 366 | 1-3 | 132 | 164 |

| VS 3.8x36 | 3800 | 36000 | 408 | 1-3 | 160 | 187 |

| VS 4x36 | 4000 | 36000 | 452 | 1-3 | 160 | 195 |

Litšoantšo tsa libaka tse sebetsang